Superficially, the modern gun barrel resembles very closely its ancestor

of several hundred years ago.

The old and the new both are thick-walled metal tubes.

The propellent charge and projectile occupy the breech end when the gun

is loaded, and the projectile, when fired, issues from the muzzle end.

But with this the resemblance ends.

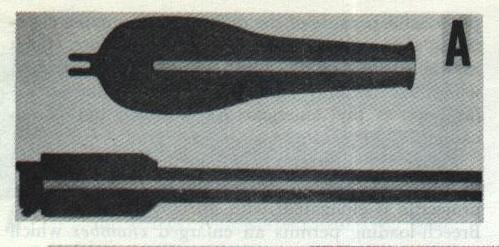

Figure 5B7 A and B shows in cross section the old look

and the new in gun barrel profiles.

The difference in shape is very significant.

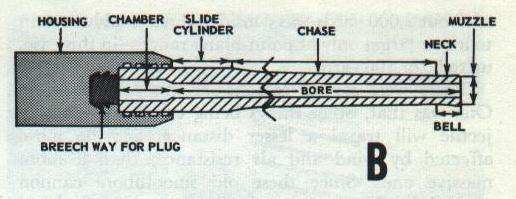

The figure also points out the main features of the contemporary gun

barrel.

Let us now consider these more closely.

1. At the breech end is a plug or breechblock which can be opened for

loading the gun.

Breechblocks take various forms; the illustration shows (as viewed from

above) the general structure associated with the sliding-wedge type used

in 5-inch mounts.

Early guns, except for a few custom-made small-arms weapons, were almost

invariably muzzle loaders; breech loaders were rarities.

Hence the silhouette representing the old gun shows no breech plug.

2. Just forward of the breech plug is an enlarged chamber to contain the

propelling charge.

3. The bore is rifled—a set of spiral grooves twists the projectile as

it moves toward the muzzle, so that it is spinning when it leaves the

gun.

Old guns as a rule were smoothbores.

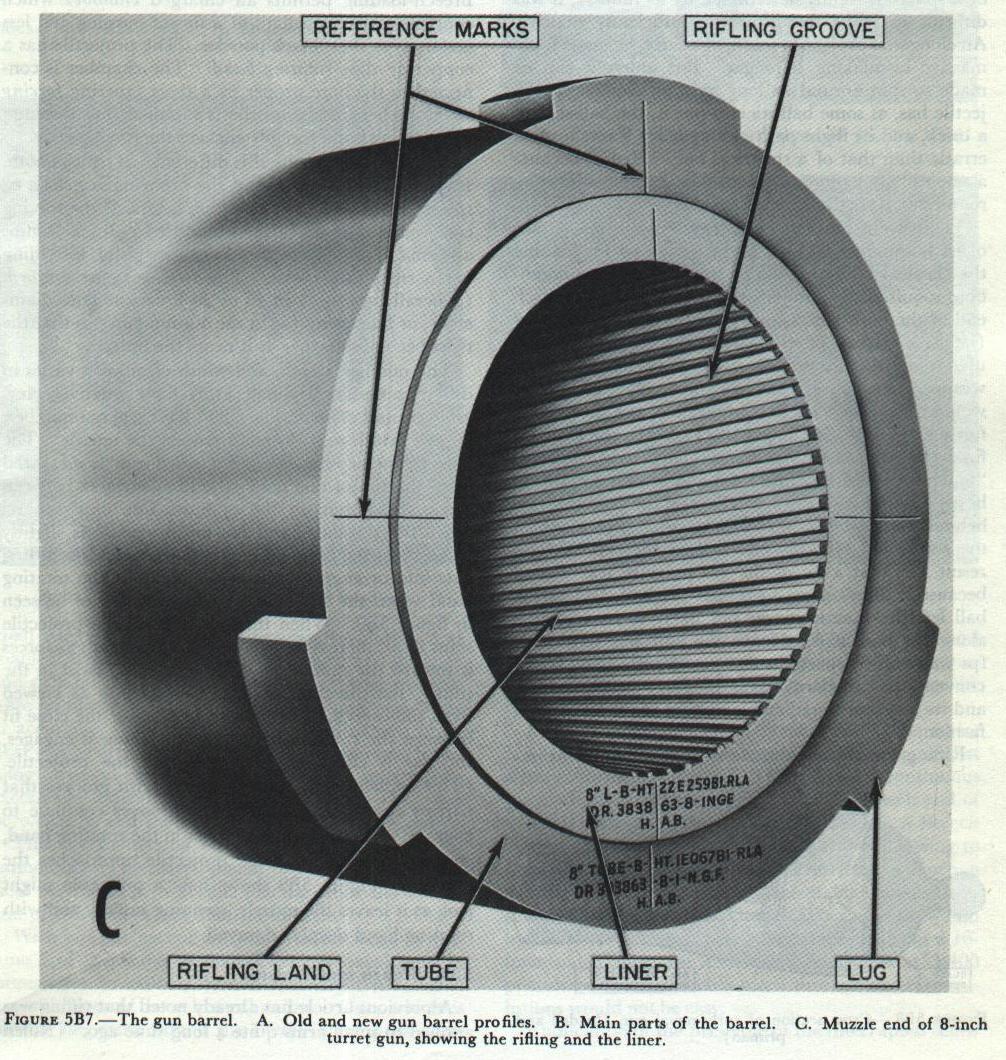

In newer types of larger guns, the rifling is cut in a liner—a tubular

insert that can be replaced when worn.

Figure 5B7 C shows the rifling cut into the liner of an

8-inch turret gun of recent design. The liner reference marks are used

for aligning the liner in the gun tube.)

In other guns, the rifling grooves are cut into the barrel. 4. As

compared with early guns, the barrel walls are much thinner in modern

guns, and the taper is much less exaggerated. Improved propellants and

improved steels have together brought about this silhouette. Common

external features are pointed out in Figure 5B7 B. Many

guns have a bell at the muzzle, where the metal is made thicker to

discourage any tendency to split. Most modern weapons lack a bell, or

instead have lugs, which are utilized when the liner (see No. 3 above)

is replaced. (The lugs serve to anchor the tool used for pulling the

liner out. ) The thinnest part of the barrel, just aft of the bell, is

the neck. Then comes the tapering chase, followed by the slide cylinder,

which moves in a bearing in the slide during recoil. The after part of

the barrel is secured to the gun housing. In the conventional 5-inch

gun, the breechblock slides up and down in a grooved rectangular

breechway in the housing. Now consider what is between the exterior and

the interior surfaces of the barrel. —the steel itself. Looking at the

profiles of guns old and new (Figure 5B7 A and B), it’s

evident that although both taper from a wide breech end to a narrower

muzzle, the taper is much more drastic in the older weapon.

Superficially, this difference in silhouette may seem a small matter,

but it is actually very important. It indicates the revolutionary

developments in propellants and in metallurgy that differentiate the new

from the old. Consider what happens when the propellant in a gun is

ignited. As it burns, it turns to hot gas under terrific pressure—up to

60,000 psi in small guns, up to 40,000 psi in larger guns. As the

projectile moves along the bore toward the muzzle, the gas pressure goes

down. It follows, then, that the chamber wall should be the thickest

part of the gun barrel, with the taper from breech to muzzle reflecting

the decreasing gas pressure behind the projectile. However, when black

powder was the propellant, the chamber had to withstand the initial

shock of this propellant’s exceedingly rapid burning rate. Thus, before

the projectile was well along the bore, the propelling charge had

already developed its maximumpressure as a sudden shock, and the gas

pressure was falling rapidly. The breech had to be especially heavy to

withstand the shock, but the tube was short because the gas pressure

fell so rapidly. In modern guns using pyro or triple-base propellants,

the maximum gas pressure is developed far more smoothly, and declines

less suddenly. This is reflected to a great extent in the silhouette of

the modern barrel. The thinner barrel walls of modern guns are evidence

not only of more effective propellants but also of improved metallurgy

of the barrel. Before the ‘80’s of the last century, the surest way to

make the barrel of a gun withstand more pressure was to make it thicker.

But there were limits to this method. Then it was discovered that by

prestressing, it was possible to make a gun barrel more resistant to

internal pressure. The earliest method of applying this principle was to

heat steel ring-shaped jackets, or hoops, to high temperatures, then

slip them over the gun tube and allow them to cool. As the hoops cooled,

they contracted, until at the end of the process they were squeezing the

gun tube inside with a pressure of thousands of pounds per square inch.

Guns so constructed are known as built-up guns, and are still made in

sizes over 8-inch. About the time of World War I, the same principle was

applied to monoblock (one-piece) guns in the radial-expansion or auto

frettage process. In this process, a single steel gun tube whose bore is

slightly smaller than the caliber desired is filled with hydraulic

fluid. The pressure is then built up enough to enlarge the bore

permanently about 6 percent. When the pressure is released, the outer

layers of the tube tend to return nearly to their original dimensions,

while the inner layers, which have been considerably enlarged, tend to

maintain their increased diameter. The result is that the inner layers

of metal are severely compressed by the contracting force of the outer

layers, just as if a hoop or jacket had been shrunk on. In other words,

the tube is “self-hooped. ” The big advantages of the radial-expansion

mono-bloc gun over the built-up type are simplicity of manufacture and

comparatively low cost and weight. Because of the difficulty of working

on the single huge forgings required for guns over 8-inch, though,

larger weapons are still built-up. Or the two methods of prestressing

may be combined.

Rifling

Early guns were capable of hurling a projectile to a respectable range,

all things considered. Large cannon could heave an iron or stone ball at

a target a couple of miles away, and actually overshoot. But their fire

was so inaccurate that a gun capable of an extreme range of about 2,000

yards was considered reasonably certain to hit its target only at

point-blank range—in this case, up to 80 or 100 yards. There were

several reasons for this poor showing. One was that, other things being

equal, a light projectile will travel a lesser distance, and be more

affected by wind and air resistance, than a more massive one. Since

these old smoothbore cannon could fire only round shot (and the maximum

volume of a sphere is rigidly determined by its radius), it was

difficult to make the projectile sufficiently massive. An elongated

projectile could, of course, be made more massive by making it longer.

But unless it can be made to spin around its long axis, an elongated

projectile has, as some ballisticians put it, the ballistics of a brick,

and its flight path or trajectory is much more erratic than that of a

spherical one. Hence, because a smoothbore cannon cannot make its

projectile spin, round shot were the only alternative. There were other

reasons, too, for the inaccuracy of early gunnery.

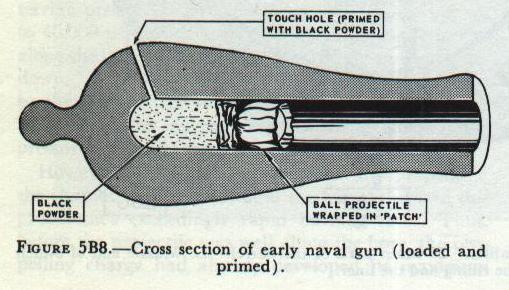

One standard method for loading the classical type of seagoing

muzzle-loading smoothbore required the gunner first to ladle into the

breech end of the bore a measured quantity of black powder (later, a

paper- of cloth-wrapped “cartridge” was used), and then to ram down

the bore the round shot wrapped in a fabric “patch. ” Since close

clearances would have made loading impossible, the shot was a fairly

loose fit. See Figure 5B8. When the gun was fired (by

lighting off a priming mixture which filled a “touch hole” leading

into the blind breech end of the bore), the patch was supposed to seal

the powder gases behind the loose-fitting ball projectile. But much of

the gas would blow by one side or the other. The result was that a lot

of the gas pressure was wasted because it didn’t serve to propel the

ball, and as the ball left the muzzle it was not likely to be

traveling along the bore axis. Hence the ball was slow (300 fps was a

likely speed, as compared with 2,700 fps in conventional modern naval

medium-caliber guns), and its trajectory predictable only in the most

general fashion. Rifling the oldtime muzzle-loading cannon was

impracticable because of the difficulty of ramming closefitting

ammunition down the length of the bore. Such ramming was possible only

in small arms (which is why rifled shoulder weapons were used by

infantry as far back as the American Revolution), but not in cannon.

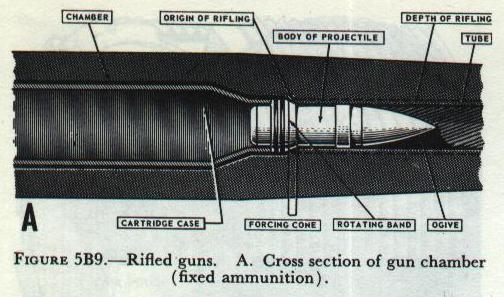

Figure 5B9 A illustrates how these problems are

solved in modern conventional naval guns. First of all, the projectile

is elongated, with an ogival forward end. Breech-loading permits an

enlarged chamber which contains more propellant of a slower burning

and less erratic type than black powder. The projectile has a copper

or alloy rotating band. The chamber is connected to the bore proper by

a short tapering forcing cone. When the projectile is rammed into the

gun, the rotating band forcibly engages the forcing cone.

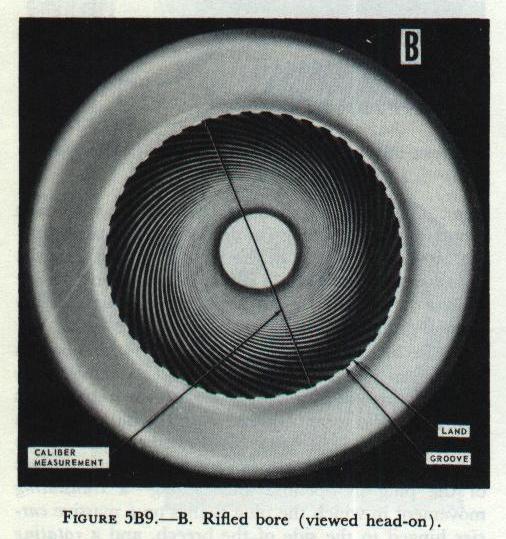

And the gun bore itself is different. It isn’t smooth. It is grooved

or rifled, and the grooving is helical or spiral. See

Figure 5B9 B. The rifling begins at the forcing cone

and continues to the muzzle. In all naval guns and small arms except

the .45 caliber pistol, the rifling has a right-hand twist. The twist

may be uniform (generally around 1 in 15 or 20 times the bore

diameter), or increasing (as in the 40-mm gun) so that the twist

becomes sharper as it nears the muzzle. The number, depth, and width

of grooves varies in different designs. Small arms have relatively few

grooves, and cannon (fig. 5B9) have a large number. Groove width may

decrease toward the muzzle.

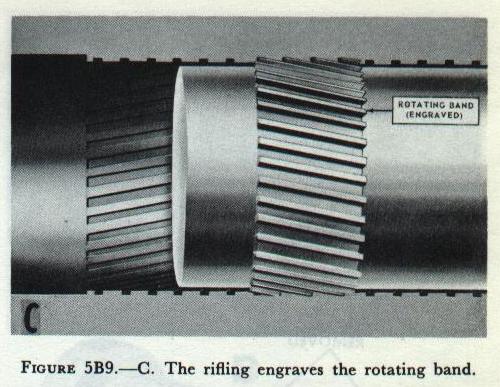

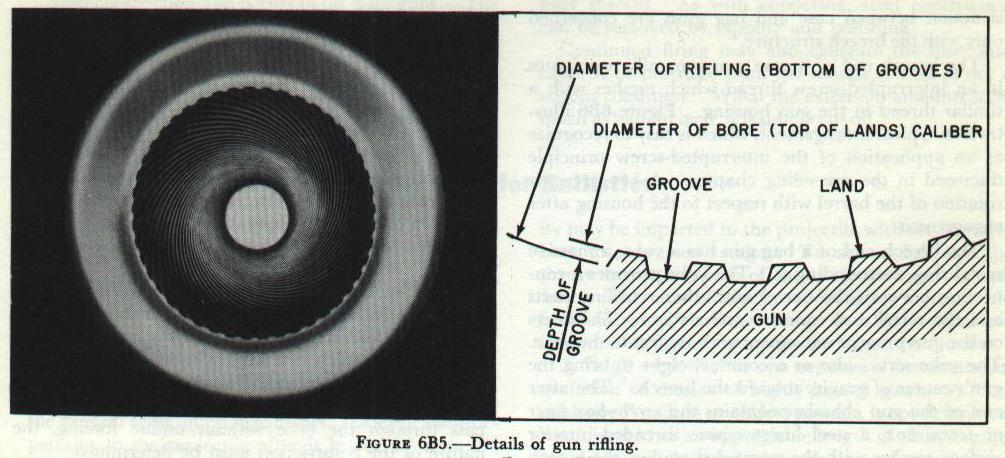

The bore diameter or caliber of a rifled gun is measured from the top

of one land (the high surfaces between grooves) to that on the

opposite side of the bore. Since the rotating band for the projectile

is slightly larger than the nominal gun bore diameter, the rifling

cuts into or engraves the softer metal of the rotating band when the

projectile is rammed, as can be seen in Figure 5B9 C.

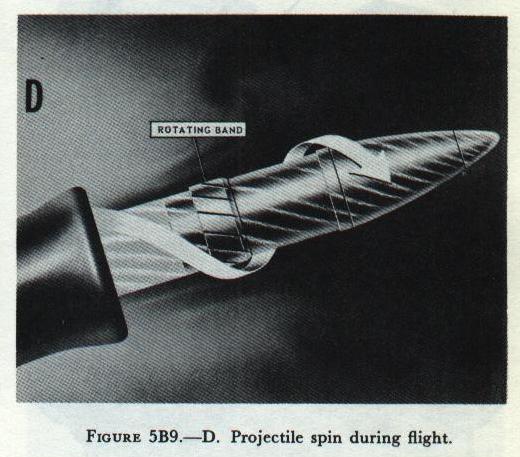

When the gun is fired, the projectile spins at an increasing rate as

the propellent gas forces it toward the muzzle. (With right-hand twist

in the rifling, the direction of spin is clockwise as viewed from the

breech. ) Moreover, because of the close fit between the rotating band

and the rifling it engages, the gas is effectively sealed behind the

projectile. (This explains why rifling is made with grooves that

narrow toward the muzzle; the grooves continue to engrave wider and

wider notches in the rotating band, ensuring a tight fit as the

projectile approaches the muzzle. )

Figure 5B9 D shows how a projectile might look as it

leaves the muzzle, spinning rapidly and with rotating band deeply

engraved.

Breech Mechanisms

Rifling was applied to small arms quite a long time ago. Rifled small

arms were used in the American Revolution, and enabled American

sharpshooters to stand at a distance and pick off the redcoats, whose

smoothbore muskets were no match for the American rifles either in range

or accuracy. ) But it could not be applied in a practical way to

artillery, either seagoing or ashore. Ramming large-caliber ammunition

from the muzzle was excessively difficult if the projectiles fitted the

rifled bore closely, and the rifling was useless if they didn’t.

The key to making effective and practical rifled cannon lay in the

development of effective and practical mechanisms to permit loading from

the breech end of the gun rather than the muzzle. With but one

exception, all naval guns in present use in calibers 44)-mm and larger

use 1 of 2 general types of breech mechanism. One, which is used in bag

guns only, is the Welin interrupted-screw type. The other, used in

40-mm, 3-inch, 5-inch, and 6-inch guns, and in 8-inch turret guns for

case ammunition, is the vertical sliding-wedge type. Consider the

interrupted-screw type first. Interrupted-screw breech mechanism. The

screw is a widely used device for securing something against a heavy

thrust.

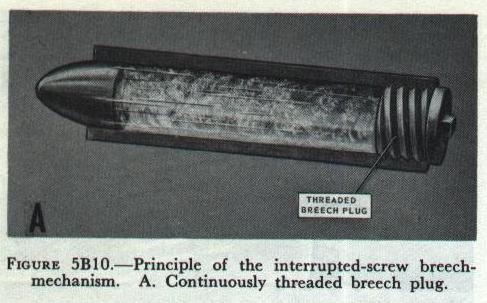

Figure 5B10 A shows how a continuous screw closure

might be used to seal the breech end of a metal tube to make a gun of

it. Such a breech closure or plug would of course require unscrewing

to open the breech after firing. The mass of such a device, designed

to withstand the 40,000 psi gas pressure developed in a typical

large-caliber cannon, would inevitably be considerable. (The breech

plug of a 16-inch naval gun, for example, weighs about 1,400 pounds. )

Turning such a screw through several revolutions would not be easy.

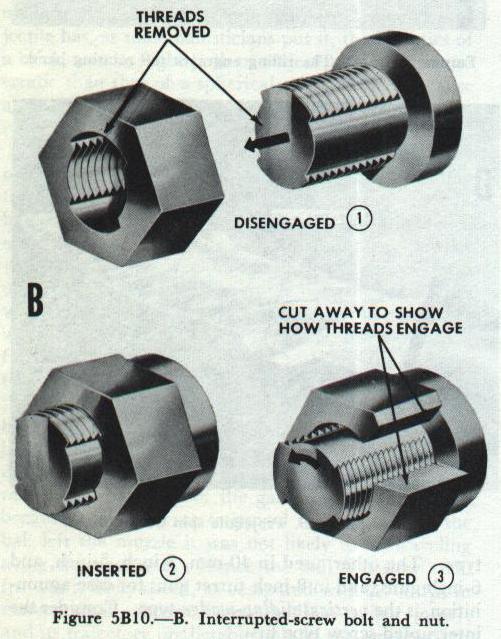

Application of the principle of the interrupted screw reduces the

number of turns required to a fraction of a revolution. If half the

threaded area is removed from a bolt (representing the breech plug)

and the nut (representing the breech or screw box), then it is

possible to insert the bolt Figure 5B10 B and engage

the two by turning the bolt 90° (3 in Figure 5B10).

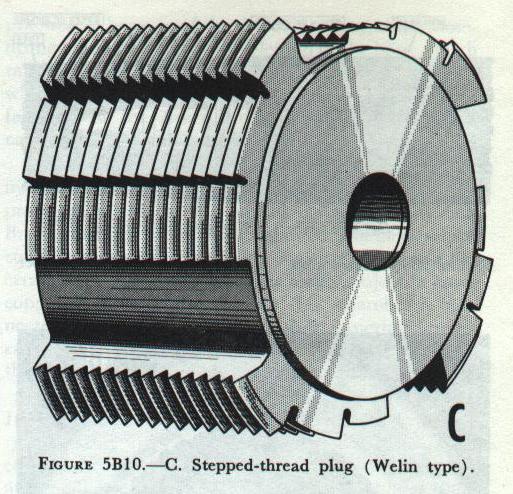

Figure 5B10 C Stepped-thread plug (Welin Type). The

disadvantage of this straightforward application of the

interrupted-screw principle is that half the threaded area must be

removed, and this reduces the “holding power” by reducing the amount

of thread area that can be engaged. This disadvantage is partly

obviated by the Welin stepped-thread breech mechanism. In this

arrangement, both plug and breech have steps. The steps are arranged

in groups, with each group of four ascending (or descending) steps

occupying one 90 degree sector. On the plug (Figure 5B10), the lowest step of each group is blank, and the others are

threaded. On the breech screw box the highest step in each group is

blank, and the others threaded.

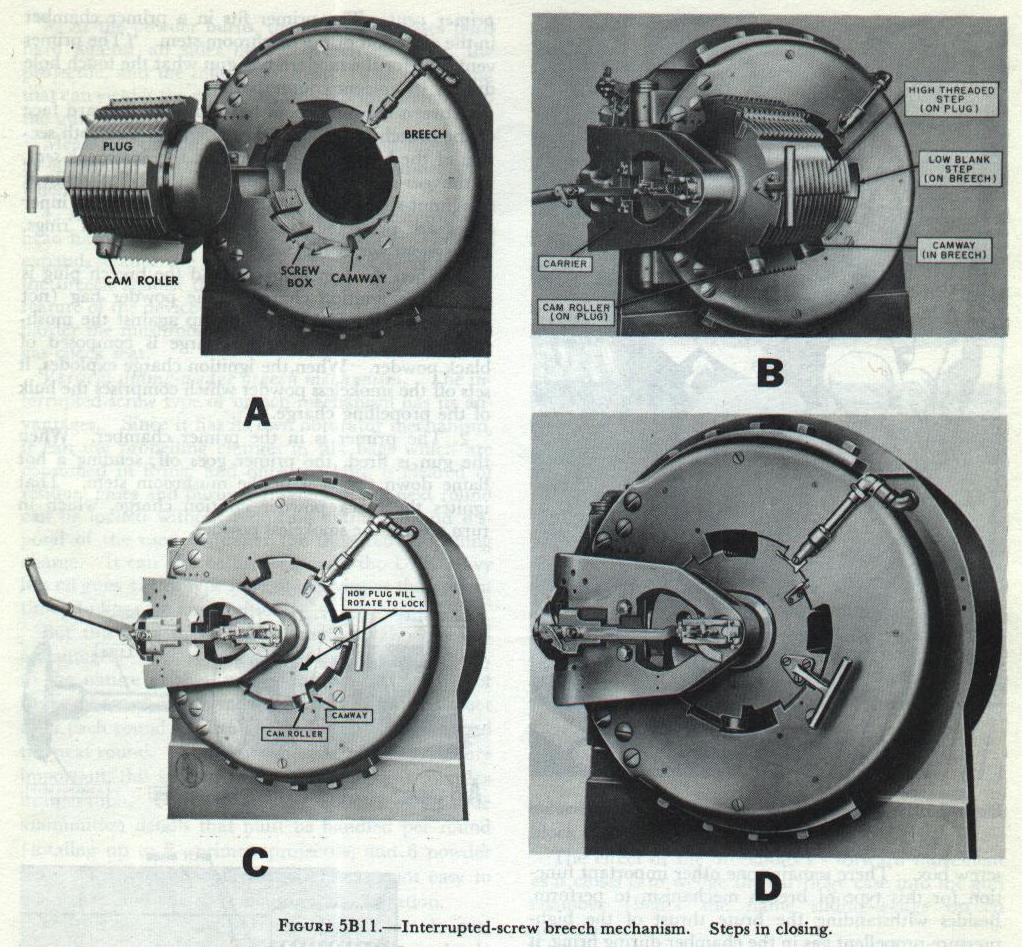

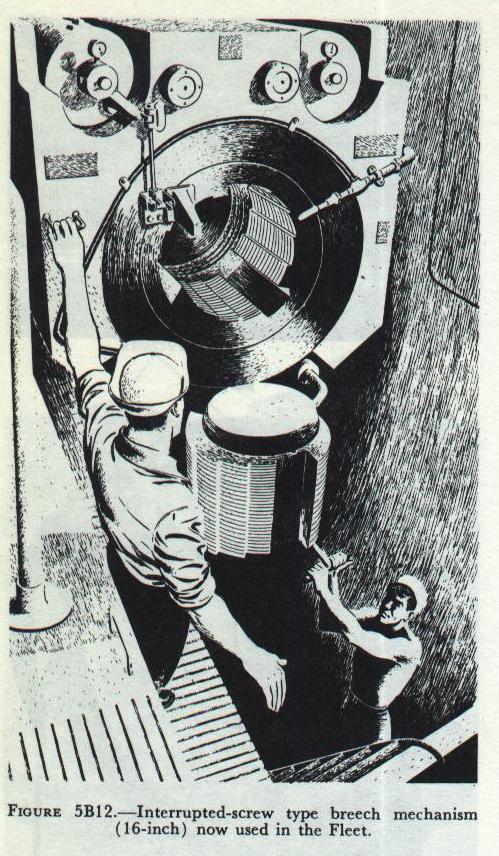

Figure 5B11 shows how an obsolete 14-inch breech

mechanism functions in closing. The principle is the same on

present-day 8-inch and 16-inch hag guns now in the Fleet, but in those

ships the plug swings in a vertical arc (as in

Figure 5B12) rather than a horizontal one. Note that

there are two distinct motions of the plug in opening and closing - a

translating movement in which the plug swings on a massive carrier

hinged to the side of the breech, and a rotating motion in which the

plug screws into the screw box. Both of these may occur together in

the final stages of dosing or the beginning of opening. Now follow the

breech-closing action as illustrated in Figure 5B11:

1. From its open position, the plug swings around toward the screw box.

As the plug moves in, each high threaded step of the plug fits into a

low blank step of the screw box (fig. 5B11). The high threaded steps on

the screw box fit into the low blank sectors of the plug. The other

threaded steps also clear each other in this position.

2. When the plug is well into the screw box, but has not yet begun to

rotate, a cam roller on the plug contacts a camway in the screw box.

(Figure 5B11 shows how the plug must rotate to engage

the screw box. )

3. During the last part of its translation into the screw box, the

plug’s cam roller engages the camway and the plug turns so that the

mating threads on box and plug engage.

Figure 5B11 shows the breech closed, locked, and ready

for firing. Notice the two great advantages of the Welin-type screw box

and plug:1. About 75 percent of the engaging surfaces of plug and screw

box are threaded. 2. The plug requires only about 27. 5 degrees of

rotation for full engagement and locking.

Compare these characteristics with the original bolt and nut, and you

can see the improvement. Welin-type breech mechanisms may have 3, 4,

or even 5 steps, counting the blank sectors. In most modem

installations, the plug swings vertically up into the screw box

(Figure 5B12) rather than horizontally as in the

14-inch breech pictured in Figure 5B11. Because of

the large size of the guns on which they are generally found,

interrupted-screw plugs are too heavy for unassisted operation by

hand. (As noted above, on a 16-inch gun the plug may weigh as much as

1,400 pounds. ) Interrupted-screw mechanisms for these large guns are

therefore generally fitted with air- or spring-powered devices to aid

the gun crew in operating them.

The discussion of the interrupted-screw type breech mechanism so far has

concentrated on the principles of operation of the engaging parts - the

plug and screw box. There remains one other important function for this

type of breech mechanism to perform. Besides withstanding the brute

thrust of the high-pressure propellent gas in the chamber during firing,

it must also prevent leakage of the burning, toxic gas into the turret

or mount. It does this by means of an obturator or sealing device - the

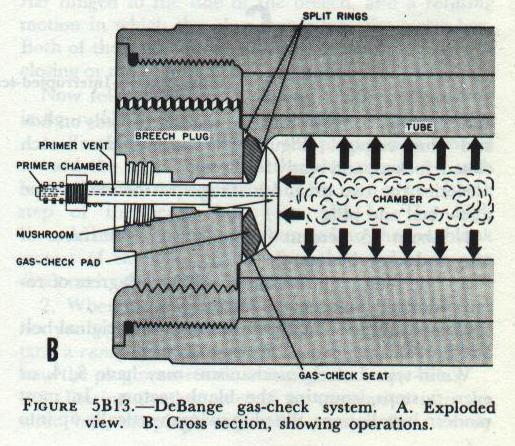

DeBange gas-check system.

The DeBange gas-check system is

used in all United States Navy bag guns. Its main parts are the

mushroom, gas check pad, split rings, and gas check seat.

Figure 5B13

Figure 5B13 A shows a typical gas-check assembly.

The

biggest component is the mushroom. (In a 16-inch gun it weighs 220

pounds.) It consists of a large flat steel head at the forward face of

the plug, with a long steel stem extending through a hole in the plug

and protruding from its rear face. Through the center of the stem and

head passes a hole called the primer vent. The primer fits in a primer

chamber in the after end of the mushroom stem. (The-primer vent does for

the modern bag gun what the touch hole did for its ancient

counterpart.)

Between the mushroom head and the forward face

of the breech plug, and bearing against a smooth section of the breech

chamber called the gas-check seat, is the gas-check pad. This is a thick

flat resilient doughnut-shaped disc of plastic, whose outer and inner

edges are protected from wear by steel split rings.

The

system works this way:

1. When the gun is loaded and the

breech plug is closed, the ignition charge in the powder bag (not shown

in

Figure 5B13 B) is right up against the mushroom

head. (The ignition charge is composed of black powder. When the

ignition charge explodes, it sets off the smokeless powder which

comprises the bulk of the propelling charge.)

2. The primer

is in the primer chamber. When the gun is fired, the primer goes off,

sending a hot flame down the vent in the mushroom stem. That ignites the

black powder ignition charge, which in turn sets off the smokeless

powder.

3. As the powder burns, the expanding gases push hard

against all sides of the breech chamber, the projectile, and the

mushroom head. The only thing that can yield is the projectile, which

begins to move up the gun bore.

Meantime the pressure goes

higher and higher up to 40,000 psi until the projectile is fully under

way, when the pressure tapers off.

4. As the pressure

increases, it shoves the mushroom head hard back against the gas-check

pad. The pad expands against the gas-check seat, effectively sealing the

breech against the escape of gas. And note this feature of the device -

the greater the gas pressure, the harder the mushroom compresses the pad

against the gas-check seat. Vertical sliding-wedge breech mechanism. The

interrupted-screw type of breech mechanism has its advantages. Since it

has its own obturator mechanism, it can use propelling charges in silk

bags which are consumed in firing, and once the bore is cleared of

residual gases and burning fragments, the next round can be loaded

without requiring extraction and disposal of the used container for the

fired propelling charge. It can also be used (though the U. S. Navy has

no guns of this type in active service at the present time) to fire case

ammunition.

But this kind of breech mechanism also has

disadvantages. One is really to be ascribed particularly to the nature

of the ammunition itself. Because of the fire hazard, a crewman must

inspect the chamber after each round fired to ensure that it is safe to

load the next round. This slows the rate of firing. More important, this

kind of breech mechanism is complex in operation. Coupled with the

number of separate ammunition details that must be handled per round

(totaling up to 8 - primer, projectile, and 6 powder bags), this type of

breech mechanism is not easy to adapt to automatic or semiautomatic

operation.

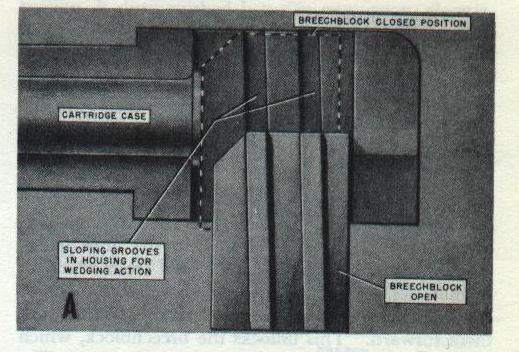

For this reason, guns 40-mm and up, of late

designs, use a breech mechanism that works on a completely different

principle - the sliding-wedge breech mechanism. This uses a sliding

element to block off the breech opening. The sliding breechblock may

move either horizontally or vertically.

Figure 5B14 A

Figure 5B14 A shows in simplified form the elements of

a vertical sliding-wedge breech mechanism as it looks from the side,

with the breechblock or plug in its lowered (open) position. The dotted

outline represents the breechblock in its raised (closed) position.

Notice that the grooves in which the plug can slide up and down are not

exactly vertical; they’re slanted slightly forward. It is clear that in

its open position the plug is noticeably aft of its closed position. Or,

in other words, in rising to the closed position, the breech-block moves

forward as well as upward.

The effect of the breechblock’s

forward movement as it closes is to wedge the cartridge case into the

gun chamber (hence the name sliding-wedge breech mechanism).

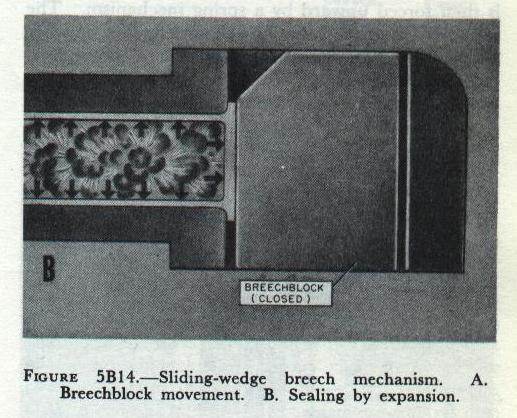

The

method of obturation used in this type of breech mechanism depends on

the cartridge case for sealing effect. There is no sealing device

incorporated into the breech mechanism.

Figure 5B14 B

Figure 5B14 B shows what happens when the gun fires. As

the propelling charge burns, the hot powder gases expand against the

sides of the cartridge, which in turn expand against the smooth walls of

the chamber and against the breech-block. Since the cartridge case

tightly seals off the entire length of the chamber, the gases can escape

only forward, driving the projectile. None can escape through the

breech. This is sealing by expansion. But after the gun fires, the

chamber is not clear. The cartridge case is not designed to disappear

with the burning propelling charge, and it must be removed from the

chamber before a new round can be loaded.

Therefore all guns

with sliding-wedge breechblocks have one or a pair of extractors as part

of the breech mechanism. In 40-mm, 3-inch, and 5-inch guns the

extractors are mechanically operated by breechblock movement.

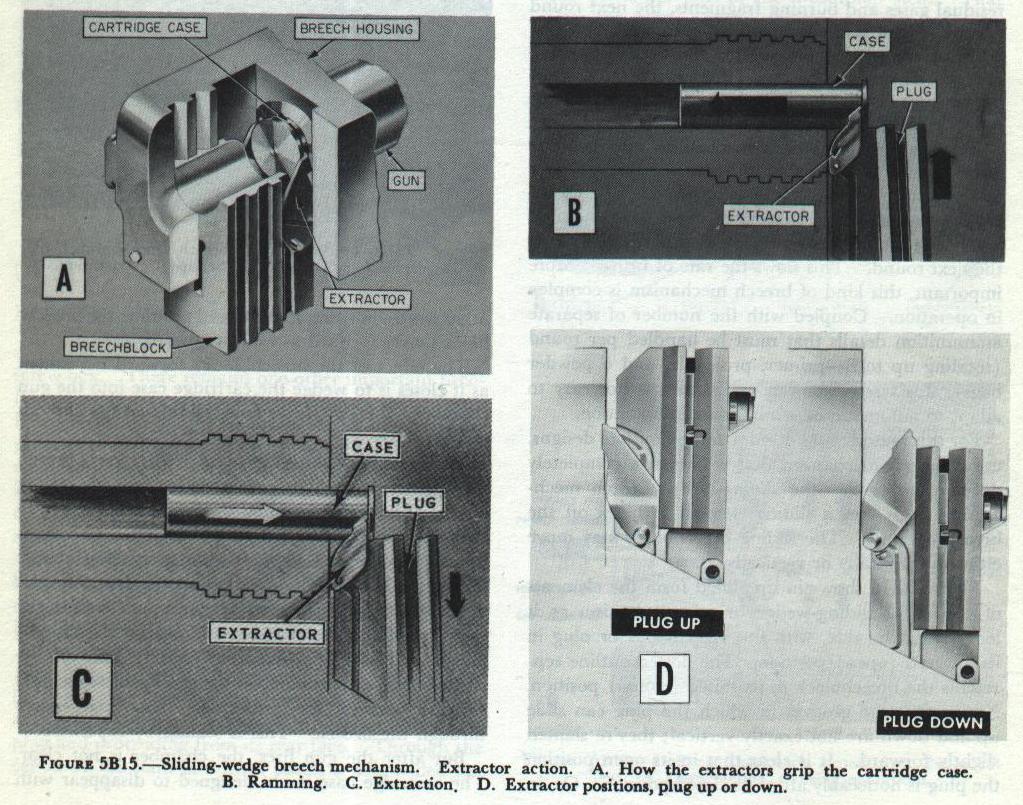

Figure 5B15

Figure 5B15 shows several views to clarify their

functioning. When the breechblock is down (open) the extractors are

pulled back. In these guns the extractors perform the dual function of

locking the breehblock down and extracting the case. As a fresh round of

ammunition is rammed into the chamber, the rim of the cartridge case

engages the extractors, and pulls them forward. This unlocks the

breechblock, which is then forced upward by a spring mechanism. The

round is chambered, the breechblock moves upward, and the extractor tips

move forward in a coordinated group of movements. When the breechblock

is fully closed, it has forced the round fully into the chamber, and the

extractor tips have seated in recesses in the housing.

After

the gun fires, the breechblock is opened by camming action. As the

block drops, the extractors retract. They haul the fired cartridge case

out of the chamber and catapult it to the rear into the slide. At the

extreme of their rearward movement, they lock the breechblock down until

the next cartridge case again pulls them forward to unlock the

breechblock.

Figure 5B15 shows the type of breech mechanism used in

conventional 3-inch and 5-inch guns. In 40-mm guns the sequence of

operations is similar, but the extractors are pivoted on a spindle, and

lock the breechblock down with a pair of hooks. In 3-inch and 5-inch

breech mechanisms the extractors are not pivoted, but rock back and

forth on their forward curved surfaces, which bear against the gun

housing. The movement of each extractor is controlled by two lugs; the

inner lug engages a camming groove in the breech-block, and the outer

one oscillates in a small curved groove in the housing. It is also

noteworthy that in 3”/50 guns equipped with power loaders the

breech-block-locking function of the extractors merely supplements the

normal functioning of another locking mechanism (described in another

chapter). But, regardless of the method of locking, the extractors

unlock the breechblock when they are moved forward by the cartridge case

being loaded.

In contrast to the sliding-wedge breech

mechanisms described above, which are operated through mechanical

camming and spring action when the gun housing moves backward and

forward in recoil and counter-coil, the breech-mechanism in 6-inch and

8-inch case guns are operated hydraulically.

The descriptions

above do not apply to the very newest designs of 3-inch and 5-inch gun

mechanisms with sliding-wedge type breech mechanisms.

Bolt-type breech mechanisms. The sliding-wedge and

interrupted-screw types of breech mechanisms are not used in guns 20-mm

and smaller. These use variants of the bolt principle. The bolt is a

breech-block which moves in line with the bore axis - forward to close

the breech, and to the rear to open it.

In so-called

bolt-action weapons like the old M1903 rifle (the famous “Springfield”

of World War I) the bolt is operated by hand.

In gas-operated

weapons like the Browning automatic rifle M1918A2 (the “BAR”) or the Ml

rifle (“Garand”) the bolt is cammed to the rear by a piston actuated by

a small amount of propellent gas diverted from the barrel while the

bullet is moving through the bore. Spring action forces the bolt forward

to ram the next round home.

In recoil-operated weapons like

the Browning machine guns, a complex of mechanical parts is forced to

the rear to varying distances by recoil, and is then driven forward by

springs to reload and fire the next round.

In

blowback-operated weapons like the 20-mm AA gun and the Thompson or M3

submachine guns (“Tommy” guns) the bolt is pushed back, when the gun is

fired, by gas pressure in the chamber, and a spring mechanism afterward

forces it forward to ram the next round home.

Aircraft

machine gun designs use all three of these actuating forces (gas,

recoil, and blowback).

Gun Barrels and Interior Ballistics

The preceding has already defined a gun as a tube designed to discharge a

projectile at high velocity by the gas pressure produced by a propellant

in the tube. Commonly, the term gun applies to the entire assembly of

which the barrel is but one part.

The gun, tube, or barrel

designates the gun tube only, and not the remainder of the gun assembly,

which includes, in addition, the mount and other parts.

This

concerns the gun barrel construction and maintenance, and with interior

ballistics - what happens inside the gun when it is fired.

Elements

of Gun Design and Maintenance

Modern requirements for gun

power

Present requirements for guns demand muzzle velocities of

from 2,500 to 3,500 fps. Lower velocities give less striking energy. More

important still, a projectile fired at low velocity would describe a curve

so high in the air, for long ranges, that hits could not be made unless

the range were known with great accuracy. Since the accurate determination

of range is a critical problem in naval gunnery, the high-power gun is a

necessity. High velocity of a projectile is produced, of course, by high

pressure upon it while traveling through the bore.

A gun may be

considered as a tube designed to withstand a given pressure from within.

In constructing such a tube, we must first consider what pressures it will

have to withstand at the various points of its length, and then make it

strong enough to insure perfect safety. The bore should also be of such

material as to stand the wear and tear of firing a large number of rounds

without being so damaged by expansion or abrasion as to interfere with the

shooting. Stresses in a gun cylinder

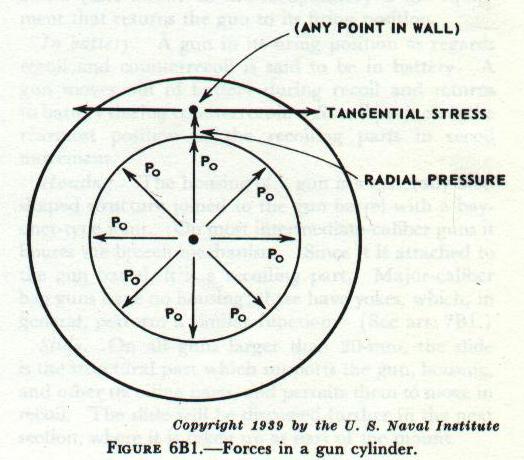

Considering a gun only as

a cylinder, we find that the two principal stresses (Figure 6B) to which

such a cylinder is subjected upon the explosion of a charge are:

1.

A circumferential or tangential stress or tension, coupled with a radial

stress, tending to split the gun open longitudinally.

2. A

longitudinal stress tending to pull the gun apart in the direction of its

length.

Experiments have shown that the greatest stress on the

metal of the gun is the tensile stress set up in the direction of its

circumference by powder gas pressure. In addition, the gun also

experiences a longitudinal stress of relatively small value. If this

longitudinal stress may be considered constant (and in guns it may be so

considered without great error) we may lay down the first of “Lame’s

laws,” as follows:

At any point whatever, in a cylinder under

fluid pressure, the sum of the tangential tension and the radial pressure

varies inversely as the square of the radius.

This law says, in

effect, that in a simple hollow cylinder under internal pressure, points

in the metal close to the bore experience a large proportion of the

stress, whereas those at a greater radius experience only a small

proportion. This means that in a simple hollow cylinder composed

throughout of metal of homogeneous physical properties, we soon reach a

limit beyond which any thickness of wall aids but little in enabling the

cylinder to withstand pressure.

Hence a modern gun would not be sufficiently strong to withstand the

required pressure if made of a single simple hollow cylinder, however

thick. But the gun must be built on a principle which will enable it to

withstand more internal pressure than could be withstood by the simple

cylinder type of construction. The problem is to make the outer layers

take a proper proportion of the stress. In one modern solution to the

problem, the gun is constructed of layers of metal. The layers nearer

the bore are held under an initial compression by the tension of the

outer layers. Thus, when the gun is fired, the inner layers must first

be expanded sufficiently to remove the initial compression before they

begin to experience a positive tension or stretch, while the expansion

is continuously resisted by the tension of the outer layers.

Properties of Gun Steel

Before considering the construction of a gun according to this

principle, it will be necessary to examine some of the properties of gun

steel which have not yet been considered.

Gun steel is

elastic within limits: thus, if a stress is applied so as to set up a

strain (deformation or change in dimension) not exceeding the elastic

limit of strain of the steel, then the steel will return to its original

shape and dimensions when the stress is removed. It is then said to have

been worked within its elastic range. However, when the elastic limit of

strain has been reached, if the stress is increased the steel will yield

rather suddenly and suffer a comparatively large strain without further

increase in stress. Thereafter increase in stress will still further

increase strain. The steel is now being worked in its semiplastic range.

(If the stress is still further increased the strain will go beyond the

semiplastic range and the steel will give rapidly and fracture, even

with decrease of load.) The important point is that the steel has now

received a permanent set or deformation. Nevertheless, it will attempt

to return to its former dimensions when the stress is removed. In other

words, it has suffered a deformation that is permanent but elastic.

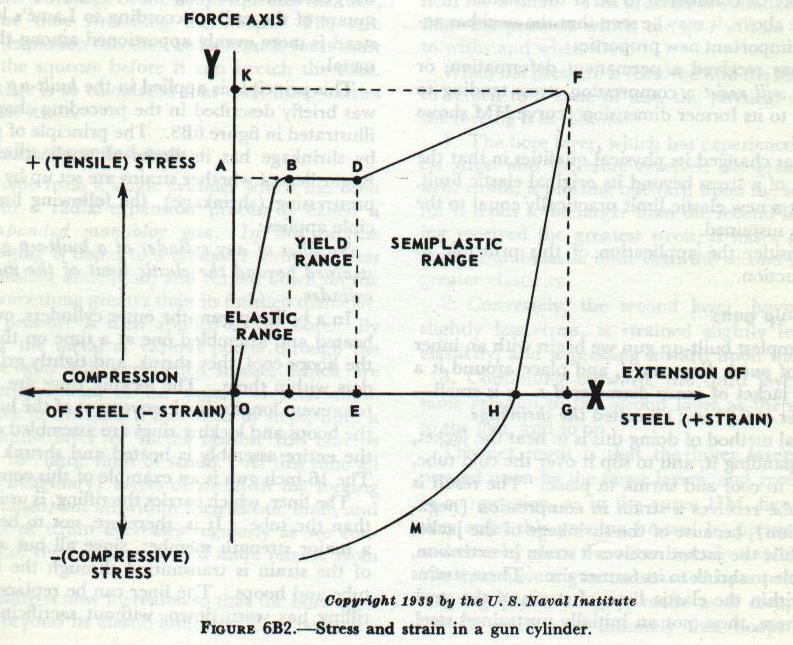

These

properties of gun steel are plotted in

FIGURE-6B2, in

which the ordinates, measured along OY, represent the stresses applied

to a test piece, and the abscissas, measured along OX, represent the

corresponding strains set up. The curve is drawn only to show tension

stresses causing extension strain in the steel, but it could be shown

that the steel behaves similarly under compression stresses causing

compressive strains.

As the stress is raised from 0 to A, the

steel is strained by the amount OC. If the load is increased slightly,

the steel yields suddenly and suffers the additional strain CE at

practically constant load. A further increase in the load to K causes an

additional strain EG. The behavior of the steel thus far is represented

by the curve OBDF.

If the load is now removed, the curve is

seen to return, not to the origin but to the point H, the line FH being

about parallel to OB. The steel has taken the permanent deformation, or

strain, OH but still has elastic properties, as is shown by the decrease

in strain from G to H upon removal of the load. HG is somewhat larger

than OC. If the same test piece is again stressed, a stress equal to OK

will be required to strain it by the amount HG; for purposes of such a

second stress, H may be considered to be at the origin.

From

the above, it may be seen that the steel has acquired two important new

properties:

(1) It has received a permanent deformation, or

strain, and will resist a compression stress tending to compress it to

its former dimension (curve HM shows this action).

(2) It has

changed its physical qualities in that the application of a stress

beyond its original elastic limit, has given it a new elastic limit

practically equal to the stress it has sustained.

Now

consider the application of this principle to gun construction.

Built-up Guns

In the simplest built-up gun we begin with an inner steel tube of outer

diameter d, and place around it a cylindrical jacket of inner diameter

d-s. s is small— on the order of 0.01 in.; s is called the shrinkage.

The

usual method of doing this is to heat the jacket, thereby expanding it,

and to slip it over the cold tube, allowing it to cool and shrink in

place.

The result is that the tube receives a strain in

compression (negative extension), because of the shrinkage of the jacket

upon it, while the jacket receives a strain in extension, being unable

to shrink to its former size.

These strains are well within

the elastic limit of strain of the steel.

We have here,

then, not an initially unstrained steel, but a compound cylinder of two

members, the inner of which has an initial strain in compression

(negative) and the outer an initial strain in extension (positive).

When

powder gas pressure (stress) is applied in the bore of such a compound

cylinder, the pressure must first expand the tube enough to remove the

initial strain of compression before it can continue the expansion

toward the elastic limit of extension of the tube.

Such

expansion is continuously opposed by the jacket, which is pressing

inward. This action may be stated in the following principle:

If

any pressure be applied to a compound cylinder, the strain at each point

will be the algebraic sum of the strain at the point before the pressure

was applied and the strain which the same pressure could cause at the

corresponding point in a simple cylinder, of the same dimensions as the

compound one.

In a compound cylinder, according to this rule,

the inner layer receives less strain in firing than would be received by

the corresponding layer in a simple cylinder, for the original

compression must first be overcome before any positive strain

(extension) can be introduced.

Correspondingly, the outer

layer receives more strain than it would in a simple cylinder plus the

original strain in extension that it receives in construction.

The stress felt by the different layers of the gun is then

no longer inversely proportional to the square of the radius according

to Lame’s law, but instead is more evenly apportioned among the layers

of metal.

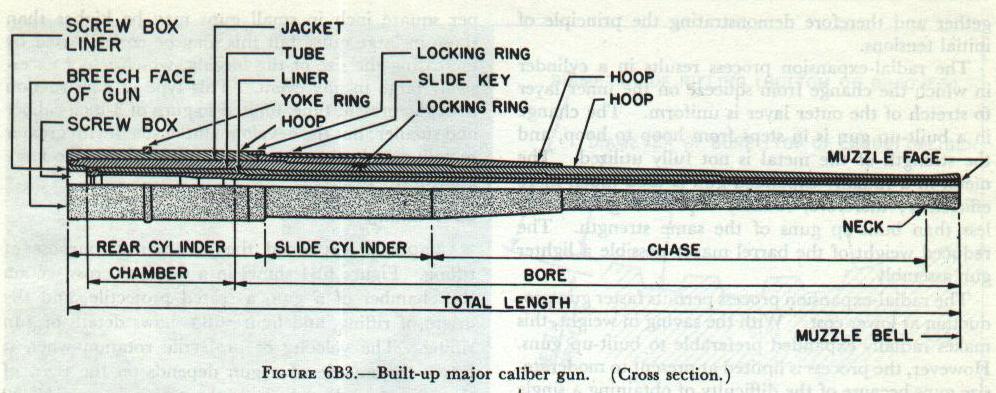

This principle is applied in the built-up gun.

Figure 6B3 The principle of prestressing by shrinkage

has its limits of application, however.

Regardless of

whether strains are set up by firing or by prestressing (shrinkage),

the following limiting principle applies:

No fiber of any

cylinder of a built-up gun must be strained beyond the elastic limit

of the metal of that cylinder.

In a built-up gun, the outer

cylinders, or hoops, are heated and assembled one at a time on the

tube.

As the hoops cool, they shrink, and tightly grip the

cylinders within them.

The locking rings are then added to prevent longitudinal movement of

the hoops.

After the hoops and locking rings are assembled

on the tube, the entire assembly is heated and shrunk on a liner.

The 16-inch gun is an example of this construction.

The

liner, which carries the rifling, is usually thinner than the tube. It

is, therefore, not to be considered a major strength member, since all

but a small part of the strain is transmitted through the liner to the

tube and hoops.

The liner can be replaced when the rifling

has worn down, without sacrificing the other parts of the barrel which

have a much longer service life.

The assembled barrel forms

a cylinder within which high pressure is developed as the charge

explodes.

The effect of the pressure is greatest on the

inner cylinder, and diminishes rapidly as it proceeds outward.

If the outer hoops were assembled over the tube without

shrinkage, they would be subjected to less strain than the tube and

the strength of gun would be little greater than the strength of the

tube.

However, the shrinkage of the hoops squeezes the

tube, at the same time stretching the hoops.

The safe

pressure of explosion can then be increased, for it must overcome the

squeeze before it can stretch the tube.

The shrinkage is so

calculated that each hoop carries a share of the strain.

Radially

expanded guns

A gun made from a single cylinder which has

been subjected to a radial-expansion process is called a radially

expanded monobloc gun.

In this process the gun forging is

bored to a diameter somewhat less than the finished dimension, and

turned down on the outside to something greater than its finished

diameter.

Hydraulic pressure is then applied to the bore.

By Lame’s law the metal at various points through the wall

of the gun will experience stresses which are inversely proportional

to the square of their radii.

The pressure in the bore is

increased in steps, until a thin, indefinite layer of metal nearest

the bore is brought to its elastic limit of strain.

At

this time all the other (imaginary) layers of metal in the forging are

also strained, but all within their elastic limit, and the amount of

strain decreases regularly as we consider layers of the metal more and

more remote from the bore.

The pressure is now increased so

that the bore layer is strained beyond its elastic limit, the layer

next outside the bore layer is brought just to its elastic limit, and

the tension in all the other layers is increased.

Still

further increase of pressure increases the permanent strain in the

bore layer ( which is now being worked in the portion of the curve

BDF, (Figure 6B2), strains the second layer beyond its elastic limit,

brings a third layer up to its elastic limit, and increases the

tension in all the other layers.

The increase in pressure

is continued until the outside layer of metal just reaches its elastic

limit of strain, and this pressure is held for a time.

This pressure is considerably greater than the pressure

which the gun will be called upon to withstand when fired.

When

the pressure is removed and the metal allowed to return to a state of

rest, the physical condition of the forging is as follows:

1.

The bore layer, which has experienced the greatest stress and

therefore received the greatest permanent strain, is pressing outward

upon the second layer, for it tends to be larger than the second

layer.

Having received the greatest stress, it has a

greater permanent-and-elastic limit than the second layer, and a

greater elasticity.

2. Conversely, the second layer, having

received slightly less stress, is strained slightly less, has less

elasticity, and is pressing inward upon the first layer.

3.

Continuing outward, the third layer bears the same relation to the

second layer as the second does to the first, and so on.

The

net result is that the inner layers are being pressed upon by the

outer layers, and receive a strain in compression, as in the curve HM,

Figure 6B2, but they resist this pressing inward by pressing outward,

and thereby place the outer layer in a state of tension.

We then have a gun constructed by a process of selfhooping

(autofrettage), made as if composed of an infinite number of

infinitely thin hoops shrunk together and therefore demonstrating the

principle of initial tensions.

The radial-expansion process

results in a cylinder in which the change from squeeze on the inner

layer to stretch of the outer layer is uniform.

The change

in a built-up gun is in steps from hoop to hoop, and the strength of

the metal is not fully utilized.

The metal in a radially

expanded gun is used much more efficiently; therefore, radially

expanded guns weigh less than built-up guns of the same strength.

The reduced weight of the barrel makes possible a lighter

gun assembly.

The radial-expansion process permits faster

gun production at lower cost.

With the saving in weight,

this makes radially expanded preferable to built-up guns.

However, the process is limited at present to

moderate-size guns because of the difficulty of obtaining a single

forging large enough for those of major caliber.

Typical

monobloc barrels are found in the 5”/38 caliber guns and the 6”/47

caliber guns.

Combination guns

The built-up and

radially expanded methods may also be incorporated in a single gun.

Thus the difficulty of obtaining a single forging big enough for the

larger guns can be overcome. The 8”/55 caliber gun, for example, has a

jacket shrunk on a radially expanded tube.

Simple one-piece

guns

Many small guns such as the 40- and 20-mm are made

from a single steel forging which requires neither radial expansion

nor hoops. The pressures developed per square inch in small guns may

be higher than those in large guns, but this may be compensated by

increasing the size of the forging, which is not excessively large in

any event. This type of construction is, at the present time, limited

to guns of 3-inch caliber and smaller; but the development of steels

with greater metallurgical strength may make it applicable to large

guns in the future.

Rifling

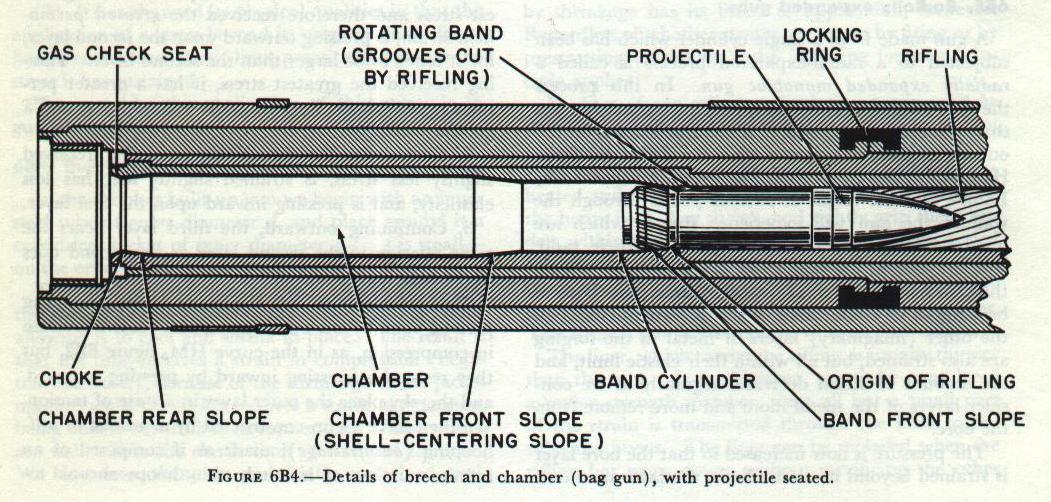

Figure 6B4

Figure 6B4 shows in a detailed cross section the

chamber of a gun, a seated projectile, and the origin of rifling, and

Figure 6B5 shows details of gun rifling. The velocity

of projectile rotation when it leaves the muzzle of a gun depends on the

twist of the rifling and the velocity of the projectile. A 16”/50

projectile turns at about 4,000 rpm when it leaves the muzzle, and a

40-mm projectile turns at about 40,000 rpm.

In guns 5-inch

and smaller, rifling is cut into the gun tube’s bore. Larger guns may be

fitted with tubular loose liners, which can be replaced with relative

ease when the rifling is worn out. The rate of rifling wear tends to

increase with caliber.

Differences in construction between

case and bag guns

Nowadays only large guns (8-inch and up)

use bag ammunition. Hence bag guns are generally of the built-up type,

while a case gun may be monobloc or built-up, depending on size. Other

differences in construction between case and bag guns are concerned only

with the breech structure.

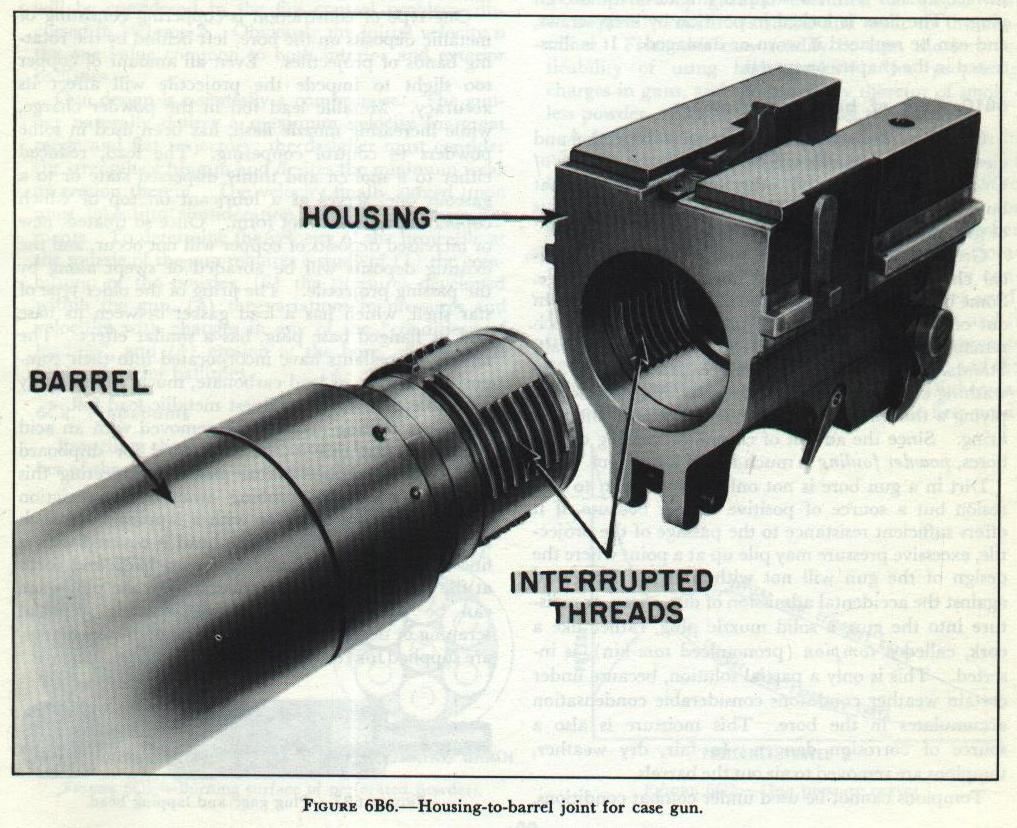

The breech end of a case gun

generally terminates in an interrupted-screw thread which meshes with a

similar thread in the gun housing.

Figure 6B6

Figure 6B6 illustrates a typical arrangement, which is

easy to recognize as an application of the interrupted-screw principle

discussed in the preceding chapter. A key prevents rotation of the

barrel with respect to the housing after engagement.

The

breech end of a bag gun has a yoke, a massive metal ring, surrounding

it. The yoke provides a connection between the barrel and other

recoiling parts and the recoil and counterrecoil systems. Shoulders on

the gun prevent movement with respect to the yoke. The yoke serves also

as a counterweight to bring the gun’s center of gravity toward the

breech. The after end of the gun chamber contains the screw-box liner or

screw box, a steel insert whose threaded interior surface meshes with

the stepped thread of the breech plug. The liner is locked in position

by keep screws, and can be replaced if worn or damaged. Care of bore and

chamber

Great heat, great pressure, and complicated chemical

changes accompany the burning of the charge. Some but not all of the

residue of the burning is blown out of the muzzle after the projectile.

That which remains in the gun is in the form of a corrosive salt.

Standard procedure is to remove this “fouling” by washing out the bore

with a hot soda solution and applying a thin film of oil before securing

until the next firing. Since the advent of chromium plating of gun

bores, powder fouling is much less of a problem.

Dirt in a

gun bore is not only an invitation to corrosion but a source of positive

danger because, if it offers sufficient resistance to the passage of the

projectile, excessive pressure may pile up at a point where the design

of the gun will not withstand it. To guard against the accidental

admission of dirt, spray, or moisture into the gun, a solid muzzle plug,

rather like a cork, called a tompion (pronounced tom-kin), is inserted.

This is only a partial solution, because under certain weather

conditions considerable condensation accumulates in the bore. This

moisture is also a source of corrosion danger. In fair, dry weather,

tompions are removed to air out the barrels.

Tompions cannot

be used under combat conditions, because of the possibility of one

inadvertently remaining in a gun when firing. However, dirt and water,

especially salt water, must be kept out of the gun; so canvas, or in the

case of small calibers, plastic, muzzle covers are used. In an

emergency, the projectile can be forced through such covers without

bursting the barrel. This procedure is, of course, subject to certain

limitations. Projectiles with supersensitive nose fuzes cannot be fired

through muzzle covers of any sort. In cold-weather operations, when

canvas covers may become ice coated, they should be removed before

firing.

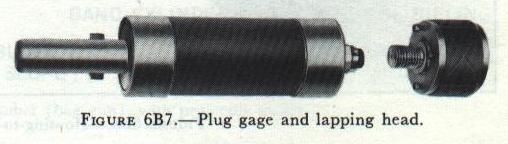

More immediately dangerous than corrosion or dirt is

metallic constriction of the bore. Before and after each firing, barrels

are tested for this condition with a plug gage, which is a steel

cylinder accurately machined to slightly under the diameter of the bore.

If at any time it is discovered that the plug gage will not pass through

the bore without undue forcing, the nature of the constriction must be

determined.

One type of constriction is coppering consisting

of metallic deposits on the bore, left behind by the rotating bands of

projectiles. Even an amount of copper too slight to impede the

projectile will affect its accuracy. Metallic lead foil in the powder

charge, while increasing muzzle flash, has been used in some powders to

control coppering. The lead, reduced either to a molten and thinly

dispersed state or to a gaseous one, serves as a lubricant on top of

which copper deposits will not form. Once so treated, new or increased

deposits of copper will not occur, and the existing deposits will be

abraded or swept along by the passing projectile. The firing of the

older type of star shell, which has a lead gasket between its base and

its flanged base plug, has a similar effect. The newest propellants have

incorporated into their composition a trace of lead carbonate, much more

readily reducible than even the finest metallic lead foil.

Copper fouling may also be removed with an acid treatment, but this is

not authorized for shipboard use. Approved mechanical means for meeting

this condition consist of rubbing away the constriction with a wire bore

brush or with a lapping head such as shown in

Figure 6B7. The head is covered with a fine abrasive material and is drawn back

and forth at the location of the constriction until the plug gage can be

passed through without forcing. Special scraping or decoppering heads,

fitted with steel blades, are supplied for certain guns. Steel

constriction also occurs in built-up guns. The friction of the

projectile on the bore tends to drag the liner along with it, which

tendency is resisted by the shoulders of the liner and the tube. With

continued firing, the shoulders of the liner tend to override those of

the tube, thereby forcing the walls of the liner inward. As with

coppering, steel constriction can be removed by lapping and

polishing.

Continued firing may also elongate the liner and

cause it to protrude from the muzzle. This is not a serious condition.

When the extension amounts to as much as half an inch, it is simply

cutoff.