1217.

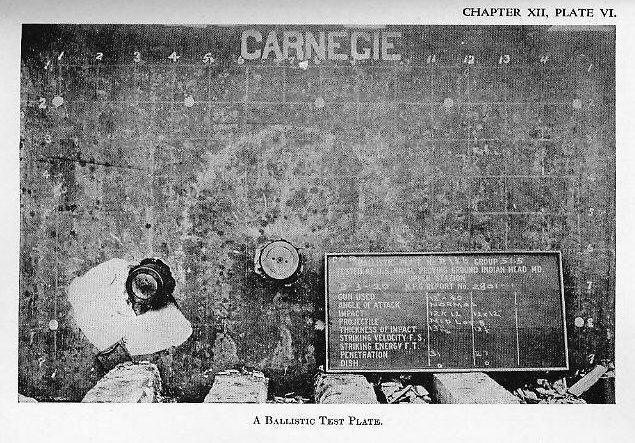

Prior to the introduction of compound or face-hardened armor all armor aboard ship was the same. It early became apparent that face-hardened armor was less effective against glancing impacts of considerable obliquity than was an equal weight of homogeneous armor. The advent of K. C. armor further strengthened this conviction. The development of a special armor to resist glancing blows dates, therefore, from the introduction of face-hardened armor. It is apparent, in the glancing blow, that a hard face is unnecessary, and that what is desired is a combination of the highest strength and ductility, in order at the projectile may be gradually deflected. In other words, against this attack, we permit the armor to give under the blow, thereby spreading the effect, while the projectile slides along the trough it creates, thus further spreading the effect, and finally is completely deflected. In a normal impact the blow is largely limited to a circular area with a diameter of about three calibers (see Plate VI), while in a glancing impact, for instance 15°, the effect of the blow is taken on an area about three calibers wide and about four to five calibers long.

Armor to resist the glancing blow is now called “Class B Armor” in the U. S. Navy, but it is also referred to as deck armor, horizontal armor, and special-treatment steel.

Nickel-steel continued to be used for horizontal armor until about 1909 when several developments took place. About that time the Carnegie Steel Company applied the newly developed nickel-chrome-vanadium alloy-steel to this armor and the change in composition and increased metallurgical skill enabled its resisting powers to be considerably increased. In that year the ballistic test of horizontal armor, for protective decks, turret tops, etc., began. About 1914 the use of vanadium was discontinued. At present, a nickel-chrome steel of approximately the same chemical composition as Class A armor is used, that is, carbon about .30 per cent, nickel about 3.85 per cent, and chrome about 1.85 per cent.

Class B armor, when less than 4 inches thick, is rolled in a mill instead of being forged, but above that thickness it is forged, as rolling thick plates is believed to work the plate less uniformly than forging, a condition which would, of course, tend to reduce ballistic resistance. Above 4 inches, if the plates are large, forging must be resorted to as there are no American rolling mills equipped to handle the required ingots. The treatment is quite different from that of K. C. armor, for desideratum is to secure great strength and ductility. Thus tensile test specimens frequently show an “ultimate strength” as high as 115,000 pounds per square inch with an “elongation” in two inches of 23 per cent and “reduction in area” of 65 per cent.

1218.

Ballistic test.-Class B armor is handled in “groups,” as is A armor, and each ballistic plate is subjected to the impact of a major-caliber projectile at angles of obliquity, depending on the thickness of the plate, from 80° up to about 55°.

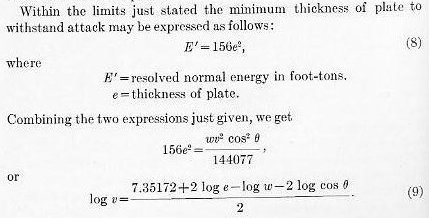

Comparisons between plates and calculations as to the suitability of plates between about 4 inches and 9 inches to meet certain conditions may be approximated by the following mathematical methods. These are not applicable to plates less than 4 inches thick.

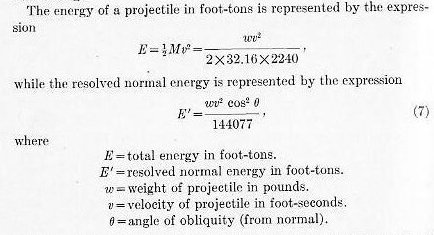

In the first place the resolved normal energy is used to represent the force acting.

As a rule the angle of attack, or the complement of the angle of obliquity, is taken in degrees as about four times the plate thickness in inches and the caliber of the projectile is taken as about two and a half times the plate thickness for 4-inch plates and twice the plate thickness for heavier plates.

As a rule the angle of attack, or the complement of the angle of obliquity, is taken in degrees as about four times the plate thickness in inches and the caliber of the projectile is taken as about two and a half times the plate thickness for 4-inch plates and twice the plate thickness for heavier plates.

Using this formula, striking velocities may be calculated upon which to base a test with a reasonable certainty that the limit of the plate may be approximately reached.

Using this formula, striking velocities may be calculated upon which to base a test with a reasonable certainty that the limit of the plate may be approximately reached.

Problem VIII.-Determine the condition under which the first shot shall be fired to determine the limit of a 5.5-inch Class B plate.

Answer: Select a 14-inch gun (projectile weighing 1,400 pounds).

Select 68° as the angle of obliquity.

Then v=1,860.3 f. s.

The above mathematical process is by no means thoroughly reliable, but it may be useful in handling comparative tests.

1219.

References made heretofore in regard to armor butts, testing, and inclined armor, and a consideration of the enormous forces concerned on impact, point out the necessity of properly securing armor the structure of the ship. Experiment only increases the importance to be attached to the subject. Many experiments have conclusively shown that all flexible mountings, such as steel springs, rubber buffers, etc., designed to absorb energy, cushion the plate, or extend the time interval in which the plate can act, are not only of no value, but are, on the contrary, a source of actual weakness.

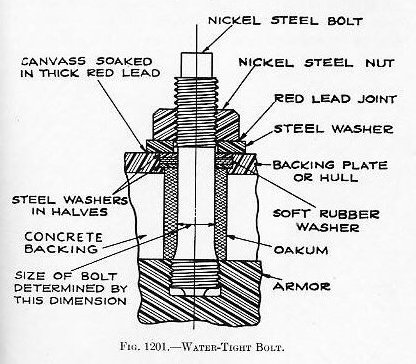

Class A armor is bolted to the skin of the ship, or to her framing and bulkheads, with heavy bolts of special design called “armor bolts.” As it is impossible to fit the armor plate snug against the shell plate, this support is provided by standing the armor off from the plating, leaving a space about 2 inches wide between the plating and the armor. This space is then filled with concrete which provides an equally distributed support to the armor over its full surface. (See Fig. 1201.)

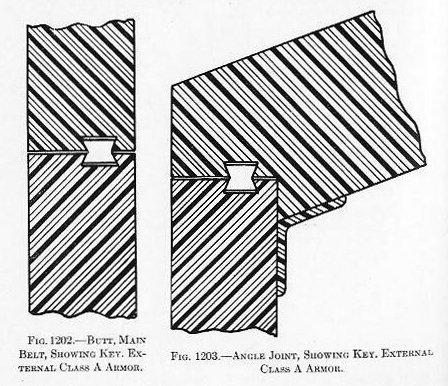

In addition to bolting, abutting edges are keyed together with a double tongue-and-groove key which is driven in endwise; and plates which meet at angles are rabbeted. (See Figs. 1202 and 1203.)

Class A armor is seldom considered as a factor in the strength of the ship’s structure.

Class A armor is bolted to the skin of the ship, or to her framing and bulkheads, with heavy bolts of special design called “armor bolts.” As it is impossible to fit the armor plate snug against the shell plate, this support is provided by standing the armor off from the plating, leaving a space about 2 inches wide between the plating and the armor. This space is then filled with concrete which provides an equally distributed support to the armor over its full surface. (See Fig. 1201.)

In addition to bolting, abutting edges are keyed together with a double tongue-and-groove key which is driven in endwise; and plates which meet at angles are rabbeted. (See Figs. 1202 and 1203.)

Class A armor is seldom considered as a factor in the strength of the ship’s structure.

Class B or deck armor, however, is generally worked into the structure. Deck armor, except with the heaviest plates, is riveted as in ordinary plating. The heaviest plates in decks and the tops of turrets and conning towers are secured with bolts in a similar manner to class A plates except no backing is used.

Armor bolts are spaced to provide one bolt for every five square feet of surface, so far as the framing behind the armor will permit, except in the case of 3-inch armor, for which one bolt is used for about six square feet of surface.

Armor bolts are made from good quality nickel steel (about 3.5 per cent nickel), for the bolt must be strong enough to hold the plate and be ductile to permit the plate to warp and spring under projectile impact without cracking.