| NAVAL ORDNANCE AND GUNNERY, VOLUME 1 CHAPTER 6 GUN BARRELS AND INTERIOR BALLISTICS |

| HOME INDEX Chapter 6 Gun Barrels and Interior Ballistics A. Introduction B. Elements of gun design and maintenance C. Interior ballistics D. Erosion E. New developments in gun design |

| C. Interior Ballistics 6C1. Ballistics Ballistics is the science of the motion of projectiles. It is divided into two branches, interior and exterior ballistics. Interior ballistics is that branch of the science which treats of the motion of the projectile while in the gun. The initial velocity—i. e., the speed of the projectile at the time it leaves the muzzle of the gun— is a result of the various forces which are involved in the general term, interior ballistics. Exterior ballistics pertains to the projectile after it leaves the gun and will be considered in the fire control problem, discussed in Volume 2. Obviously the initial velocity is the one value common to both interior and exterior ballistics. Gun design is essentially a compromise. The gunner naturally desires a maximum velocity for great range and flat trajectory; the designer must consider the strength of his gun and desires the minimum wear or erosion therein. The velocity finally agreed upon must take into consideration both of these requirements. To determine the velocity of the projectile at the muzzle of the gun requires a study of (1) the combustion of the powder, (2) the pressures developed within the gun, (3) the variations in pressures and velocities with changes in any of the “conditions of loading”, and (4) erosion at the bore. Such is the field of interior ballistics. 6C2. Propellants Propelling charges are designed to burn in the chamber of the gun in such a way that the maximum velocity may be imparted to the projectile without excessive heat, pressure, or erosion. To accomplish this the thrust against the base of the projectile must be uniform. The most efficient propellant for a gun would be so balanced that the charge is entirely consumed immediately before the projectile leaves the muzzle. A “high explosive” is one capable of instantaneous evolution of masses of highly heated gases. A “low explosive,” such as smokeless powder, is not detonated, but is burned in an appreciable length of time, causing a comparatively gradual evolution of gases, with consequently much less shock and wear to the container. From this may readily be seen the impracticability of using high explosives for propelling charges in guns, and the suitability therefor of smokeless powder. Figure 6C2 illustrates this fact. |

| A propelling charge must be suited to the gun in which it is to be used; that is, the speed of burning of the charge must, within close limits, be appropriate to the specific gun. Several factors are involved; for example, the size of the grain, the shape, the number of perforations, the web thickness between perforations, the percentage of nitration, the moisture content, the remaining volatiles, and the stabilizer used. Of these, grain size is the most easily changed, and it is varied to control the rate of burning. The percentage of nitration is fixed. The moisture content and the remaining volatiles vary with grain size. Diphenylamine stabilizer absorbs nitrous vapors, the first products of decomposition, the pressure of which would otherwise cause the generation of more vapors at a continually increasing rate. The grain shape of gun propelling charges is normally cylindrical. The web thickness and the number of perforations vary with the size of the grain. For guns smaller than 40-mm the number of perforations is 1 or none, and for larger guns the number of perforations is usually 7. See figure 6C1. A propellant’s potential is defined as the total work that could be performed by the gases of combustion while expanding from the solid state to the space they would occupy when fully expanded to atmospheric pressure and when cooled to a specified temperature. It is of interest to note that there is less stored-up energy in smokeless powder than in most common fuels. The chief characteristic of an explosive lies in its enormous rate of delivery rather than in its amount of delivery. In the average conventional gun, some 60 percent of the potential disappears in muzzle loss; 30 percent is transmitted to the projectile, and all other losses-such as heating the projectile and gun, causing the gun to recoil, and so forth-amount to about 10 percent. |

|

|

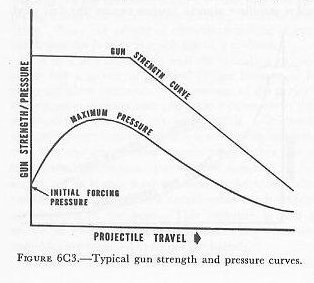

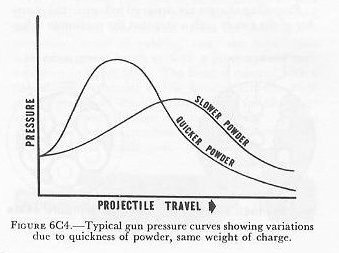

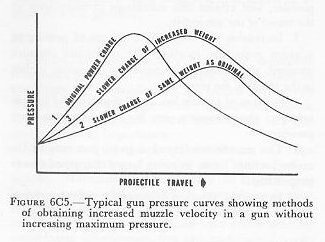

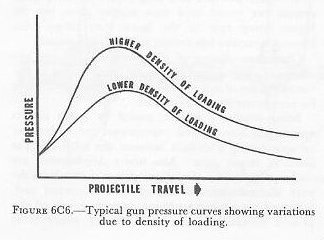

| 6C3. Gun strength-pressure relationship To establish the basic principles of gun design, study figure 6C3. The figure may be taken as typical of the strength-pressure relationship in modern guns. Note that the high breech strength is carried well forward of the point of maximum pressure. The gun strength at every point must exceed the powder pressure at that point by an amount that will provide a suitable margin of safety. The curve as it appears in figure 6C2 shows pressure beginning at a value well above zero. This indicates the pressure build-up that occurs after the propelling charge begins to burn but before the projectile begins to move. (The x-axis in the figure represents projectile movement in the bore, not time or bore length.) The projectile begins to move only after the propellent gas reaches the initial forcing pressure required to initiate movement of the projectile in spite of projectile inertia and the engagement of the rotating band in the rifling. Note that the gun strength curve is represented as a straight horizontal line above the area between the point of initial forcing pressure and the point of maximum pressure. It does not vary in parallel with pressure curve. The reason is that the same pressure that the expanding gases exert against the base of the projectile is exerted equally against all interior surfaces of the gun behind the projectile. Hence the breech part of the barrel must be designed for the maximum stress to be imposed. After the projectile passes the point of maximum pressure, it continues to be accelerated by gas pressure until it leaves the muzzle. The total area under the curve, up to the point where the projectile leaves the gun, is a rough measure of initial velocity, and the pressure remaining at the muzzle is an indication of the muzzle loss. A high muzzle pressure increases muzzle flash. 6C4. Changes in “conditions of loading” By “conditions of loading” are meant the powder used, the weight of charge, the density of loading, the volume and form of the powder chamber, and the weight of the projectile. a. Powder used and weight of charge. Powders are spoken of as quick and slow powders, these terms being used only in reference to a particular gun. A slow powder is one in which the rate of combustion is comparatively slow, and a quick powder is one in which the rate of combustion is comparatively rapid. For instance, a small-grain powder is quicker than a larger grain of the same shape, since all the grains would be consumed in a shorter time. Not only will the larger grain increase the time required for burning the charge, but it will also cause maximum pressure to be lower and to be reached later in the travel of the projectile. The gun pressure curves shown in figure 6C4 compare slow powders and quick powders where the same weight of charge was used. Within limits, the muzzle velocity for a particular gun may be increased without causing excessive pressure by increasing the size of the charge and at the same time using a powder that burns more slowly. See figure 6C5. b. Density of loading. Density of loading is the ratio of the weight of the charge of powder to that of the volume of water which, at standard temperature, would fill the powder chamber. It is a measure of the amount of space in which the gases of combustion may expand before the projectile begins to move. See figure 6C6. |

|

|

| It follows that a high density of loading leaves but little space for initial expansion, and consequently that the pressure builds up rapidly. Therefore the maximum pressure behind the projectile is reached early in the projectile’s movement through the bore. With a lower density of loading, more expansion of the gases may take place before the projectile starts to move; the maximum pressure is achieved later, and this maximum is necessarily lower than that resulting from high density of loading. Other factors remaining equal, increased density of loading increases maximum pressure, muzzle velocity, and muzzle loss. The densities of loading at present vary between 0.4 and 0.7, depending on the caliber of the gun and on whether the charge is case, stacked bag, or unstacked bag. Since the specific gravity of smokeless powder is about 1.6, the following relationship holds: Density of loading = 1.6 v, where v = the proportion of the total chamber volume which is filled by the charge. Hence it is apparent that a loading density of 0.4 would require a charge filling 25 percent of the chamber volume, and a loading density of 0.7 would require a charge filling 45 percent of the chamber volume. When the density of loading drops markedly below the above figures, irregularities of muzzle velocity may be expected. This is probably due to nonuniform ignition, excessive physical displacement of the powder grains during the burning, and an abnormal burning rate. Whatever the cause, it is evident that the pressure builds up irregularly instead of smoothly, and there is real danger that the high point will be reached at the wrong time. A practical example of this would be a projectile lodged part-way down the bore of a gun, thus greatly increasing the effective chamber volume. Not only has this the effect of greatly lowering density, thereby causing pressure waves which may build up beyond a safe limit, but it also extends the area of maximum pressure beyond the area of maximum barrel thickness. Should a normal powder charge be used to dislodge a projectile so positioned, the result would be a burst, or at least a bulge, immediately behind the projectile. Very high density of loading, on the other hand, may cause detonation of the propelling charge, again resulting in a burst gun. c. Volume and form of powder chamber. The designers of the gun, having established first the desired muzzle velocity, then the limiting maximum pressure allowable in the gun (determined from study of gun construction), can proceed to determine the volume and form of the powder chamber and the weight of the charge. Once a particular gun has been built, the volume and form of the powder chamber changes only because of erosion at the origin of rifling and improper seating of the projectile. This will cause irregular muzzle velocity. Projectiles differing in weight-for example, high-capacity and armor-piercing types-can be fired from a given gun. High-capacity projectiles, being lighter, will have a slightly higher muzzle velocity. 6C5. Summary The following conclusions may be drawn from the propellant pressure curves and the foregoing discussion: 1. High explosives are not suitable for use as propellants. 2. Using the same weight of charge, a slow powder produces a smaller maximum pressure than a fast powder, and attains this maximum pressure later in the travel of the projectile. 3. Increasing the weight of a charge of powder of a given grain size increases the maximum pressure attained and causes this maximum to occur earlier in the travel of the projectile. 4. Because of muzzle loss and irregularity of muzzle velocity, slow powders are less efficient than fast powders. 5. The muzzle velocity of a given gun may be increased within limits by using larger charges of slower propellants. 6. In general, powders designed for different classes of guns are not interchangeable. |