INDEX Back to Main Fire Control Page

A. Fire Control Problem

B. Basic elements of lead-computing sights

C. Gun sight Mark 15

D. Gun Fire Control System Mark 63

E. Gun Fire Control System Mark 56, Page 1

E. Gun Fire Control System Mark 56, Page 2

E. Gun Fire Control System Mark 56, Page 3

E. Gun Fire Control System Mark 56, Page 4 (This Page)

E. Gun Fire Control System Mark 56, Page 5

E. Gun Fire Control System Mark 56 Pg 4

26E13. Radar tracker’s station

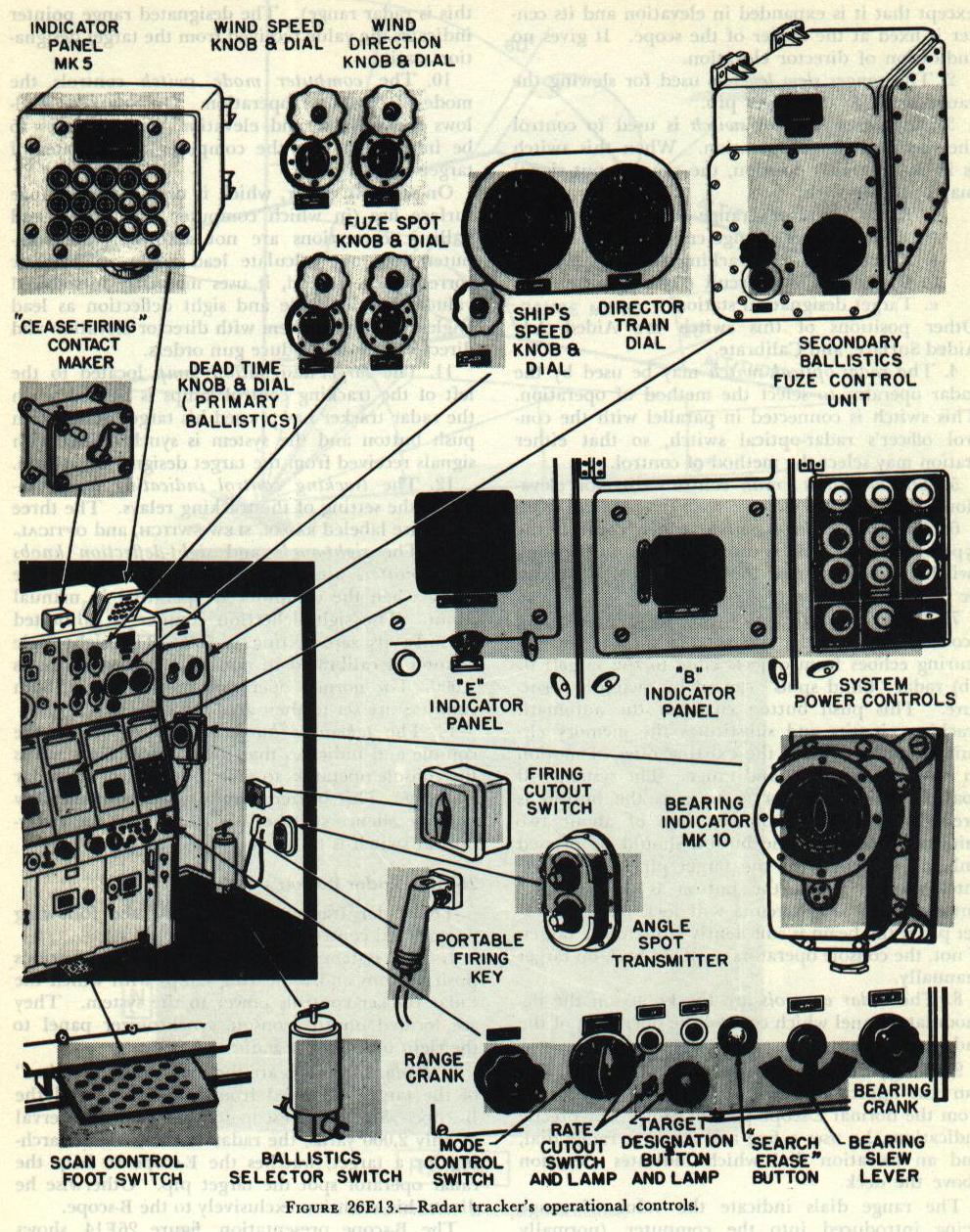

The radar tracker has available the following operational controls, figure 26E13:

1. The system power controls are the various push buttons and indicating lamps with which the radar tracker controls power to the system. They are located on the console synchronizer panel to the right of the radar indicators.

2. Radar indicators are the radar tracker’s “view” of the target, obtained from the E-scope and the B-scope. Since the B-scope covers a range interval of only 2,000 yards, the radar tracker, when searching for a target, watches the E-scope to help the radar operator spot the target pip. Otherwise he directs his attention exclusively to the B-scope.

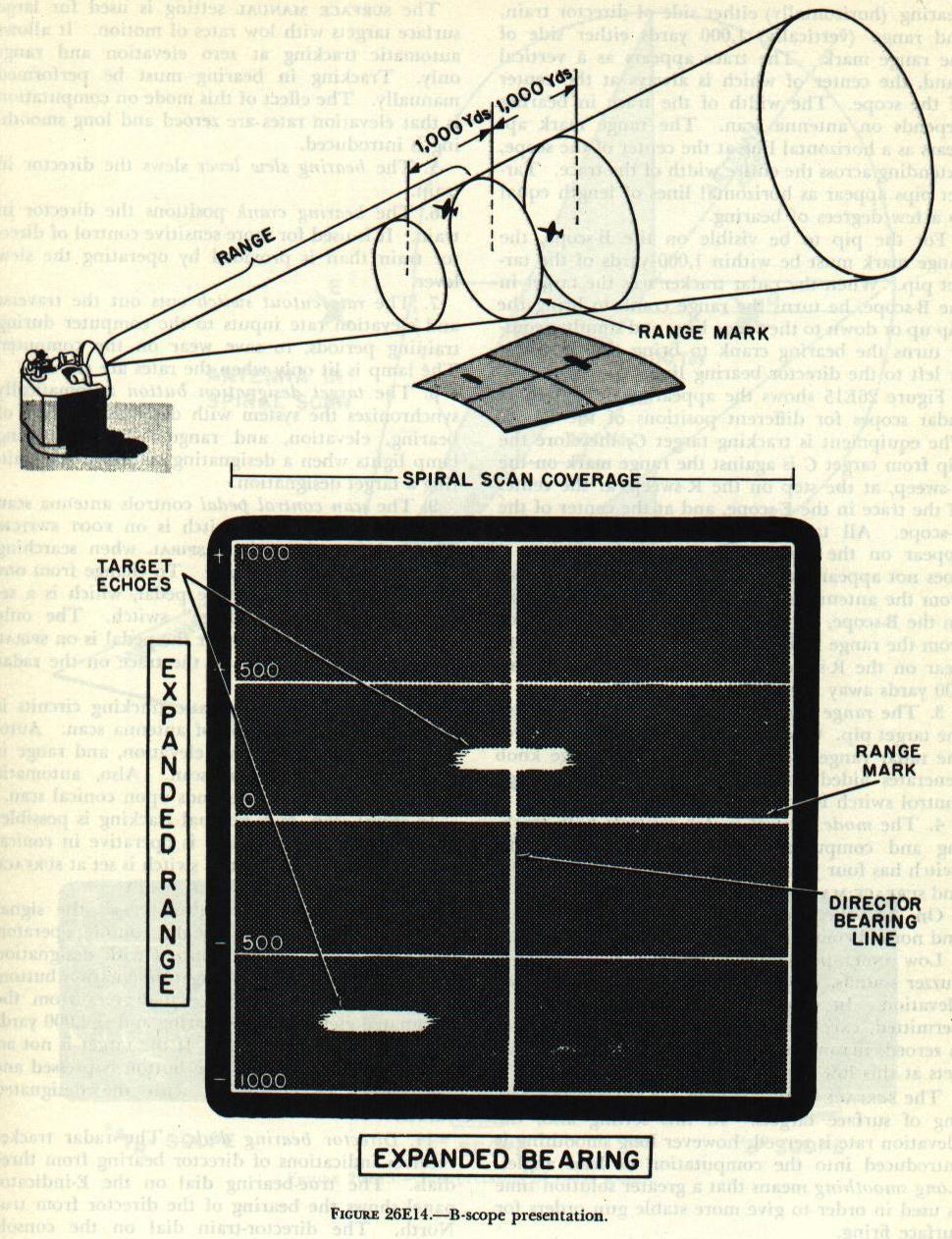

The B-scope presentation, figure 26E14, shows bearing (horizontally) either side of director train, and range (vertically) 1,000 yards either side of the range mark. The trace appears as a vertical band, the center of which is always at the center of the scope. The width of the trace in bearing depends on antenna scan. The range mark appears as a horizontal line at the center of the scope, extending across the entire width of the trace. Target pips appear as horizontal lines of length equal to a few degrees of bearing.

For the pip to be visible on the B-scope, the range mark must be within 1,000 yards of the target pip. When the radar tracker sees the target in the B-scope, he turns the range crank to bring the pip up or down to the range line, and simultaneously turns the bearing crank to bring the pip right or left to the director bearing line.

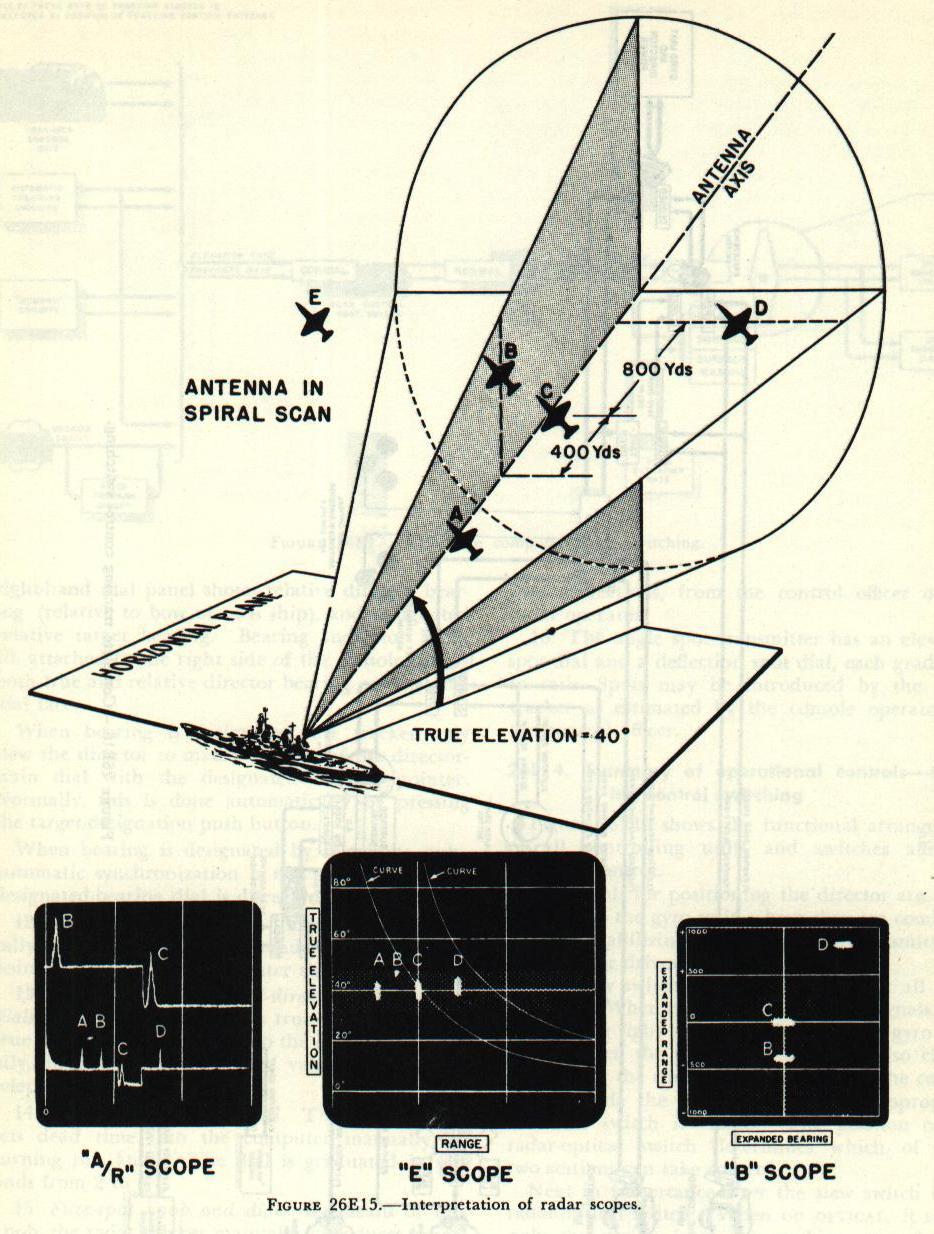

shows the appearance of all three radar scopes for different positions of the target. The equipment is tracking target C; therefore the pip from target C is against the range mark on the A-sweep, at the step on the R-sweep, at the center of the trace in the E-scope, and at the center of the B-scope. All targets covered by the spiral scan appear on the A-sweep and E-scope. Target F does not appear on any scope, because it is too far from the antenna axis. Target A does not appear on the B-scope, because it is more than 1,000 yards from the range mark. Targets A and D do not appear on the R-sweep, because they are more than 500 yards away from the range mark.

5. The range crank positions the range mark on the target pip. One revolution of the knob changes the radar range by 2,000 yards. The range knob generates aided tracking signals when the range control switch is at AIDED AA or AIDED SURFACE.

4. The mode control switch controls both tracking and computing modes of operation. This switch has four positions: AA, LOW ANGLE, SURFACE, and SURFACE MANUAL.

On AA, the usual setting, automatic tracking and normal computing are allowed.

Low ANGLE position is used when the low angle buzzer sounds, indicating a target below I degree elevation. In this setting, automatic tracking is permitted, except that the elevation tracking rate is zeroed, inasmuch as this signal is erratic for targets at this low angle.

The SURFACE setting is used for automatic tracking of surface targets. In this setting also, the elevation rate is zeroed; however long smoothing is introduced into the computation of lead angles. Long smoothing means that a greater solution time is used in order to give more stable gun orders for surface firing.

The SURFACE MANUAL setting is used for large surface targets with low rates of motion. It allows automatic tracking at zero elevation and range only. Tracking in bearing must be performed manually. The effect of this mode on computation is that elevation rates are zeroed and long smoothing is introduced.

5. The bearing slew lever slews the director in train.

6. The bearing crank positions the director in train. It is used for more sensitive control of director train than is provided by operating the slew lever.

7. The rate cutout switch cuts out the traverse and elevation rate inputs to the computer during training periods, to save wear on the computer. The lamp is lit only when the rates are cut out.

8. The target designation button automatically synchronizes the system with designated values of bearing, elevation, and range. The indicating lamp lights when a designating station is transmitting a target designation.

9. The scan control pedal controls antenna scan when the scan control switch is on FOOT SWITCH. The radar tracker selects SPIRAL when searching and CONICAL when tracking. To change from one to the other, he presses the pedal, which is a sequence-type “press-to-change” switch. The only visible indication of whether the pedal is on SPIRAL or CONICAL is the width of the trace on the radar indicators.

Operation of the automatic tracking circuits is interlocked with the type of antenna scan. Automatic tracking in bearing, elevation, and range is possible only in conical scan. Also, automatic gain control normally depends upon conical scan.

In spiral scan, only manual tracking is possible; however, the bearing crank is operative in conical scan when the mode control switch is set at SURFACE MANUAL.

10. The search erase button erases the signal super-imposed manually by the console operators when the system is synchronized with designation data. After pressing the target designation button, the operators can search ±20 degrees from the designated elevation and bearing and ±4,000 yards from the designated range. If the target is not acquired then, the search erase button is pressed and the system resynchronizes with the designated values.

11. Director bearing dials. The radar tracker receives indications of director bearing from three dials. The true-bearing dial on the E-indicator panel shows the bearing of the director from true North. The director-train dial on the console right-hand dial panel shows relative director bearing (relative to bow of own ship), and designated relative target bearing. Bearing Indicator Mark 10, attached to the right side of the console, shows both true and relative director bearing on the same dial face.

When bearing is designated, the tracker may slew the director to match the zero of the director train dial with the designated bearing pointer. Normally, this is done automatically by pressing the target-designation push button.

When bearing is designated by telephone only, automatic synchronization is not possible and the designated-bearing dial is disregarded.

12. Ship speed is normally introduced automatically, but can be set in manually by matching pointers on the inner and outer ship-speed dials.

13. Wind-speed and wind-direction knobs and dials. The radar tracker sets true wind speed and true bearing of true wind into the computer manually, in accordance with the values received by telephone.

14. Dead-time knob and dial. The radar tracker sets dead time into the computer manually by turning this knob. The dial is graduated in seconds from 2 to 6.

15. Fuze-spot knob and dial. By means of this knob, the radar tracker manually introduces range-spot corrections, from the control officer or the radar operator.

16. The angle spot transmitter has an elevation spot dial and a deflection spot dial, each graduated in mils. Spots may be introduced by the radar tracker as estimated by the console operators or the control officer.

Bottom of Page 4